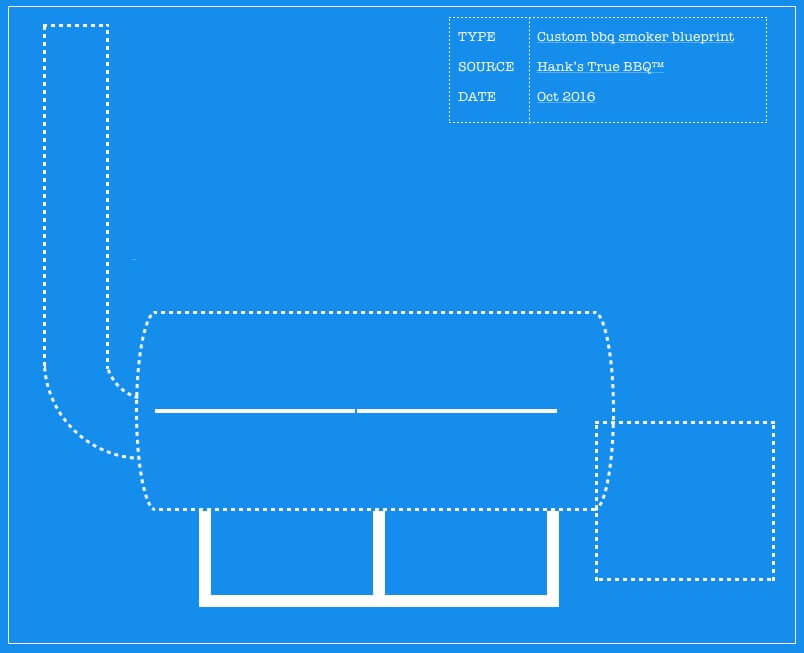

So, you plan to build an offset smoker? Congrats! It’s a large undertaking, but fun and educational. This page is thought to be your guide when building your own offset smoker.

Background

I’m an advocate for what is commonly known as ‘fat-stack’ smokers. Being an engineer means calculating and measuring, instead of just guessing. A smoker needs to breathe properly. Below follows a detailed walkthrough of all parts of a smoker, regardless of whether it is a normal one or a reverse flow smoker. I discuss what you need to think of, and also what can be ignored. My aim is to take away some of the guesswork and myths when it comes to building offset smokers. This is my manifesto.

How it works

An offset smoker is typically using wood as a fuel source. ‘Offset’ means the fire is offset, typically sideways, so you get the indirect heat setup that is key to barbecue.

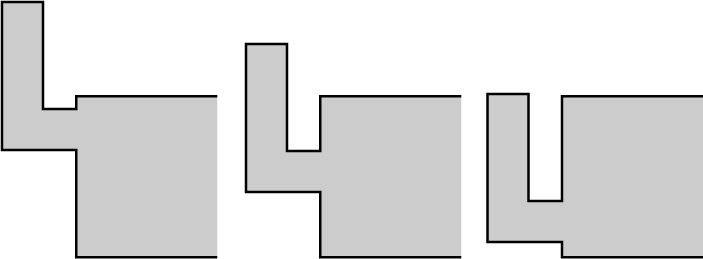

There are roughly two types of offset smokers.

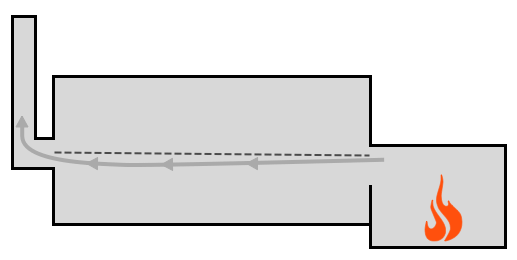

Normal offset smoker

As you can see from the illustration above, the fire is in the firebox to the right. Hot air and smoke travels through the food chamber and out through the smoke stack. This is a ‘simple’ design that works well. Depending on how it is constructed it naturally runs hotter in the firebox end of the food chamber but this can be compensated for.

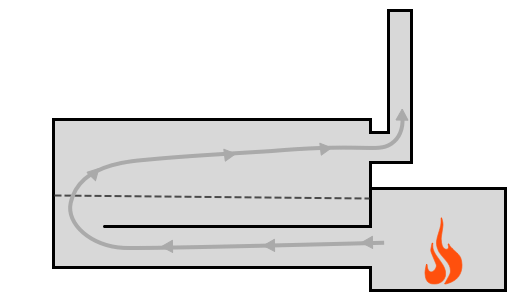

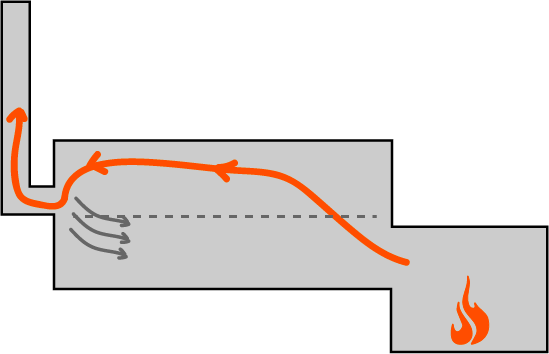

Reverse Flow Offset Smoker

As illustrated the reverse flow smoker uses a long baffle to move air all the way through the food chamber before being turned around, or reversed. This helps even out temperature differences since the radiant heat from the baffle and food chamber walls heat up the air more evenly. The drawback is that air must travel longer, thereby potentially reducing draft if it isn’t dimensioned properly. The most obvious sign of a reverse flow offset smoker is the chimney being mounted on the same side as the firebox.

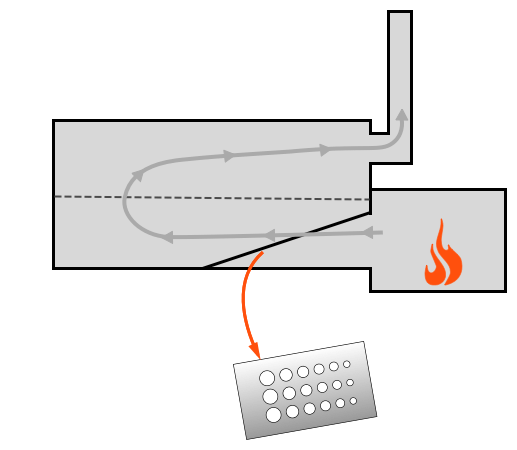

Reverse Flow Offset Smoker – a different version

The main idea behind reverse flow is (as mentioned) to reduce temperature differences in the food chamber. Completely depending on different constructions an offset smoker is typically hotter the closer to the fire you get. A common way to solve this is to use a slanting baffle perforated with different size holes. See picture above. The hot air flow is slightly redirected by the smaller holes at the top, forcing some of the hot air down where the larger holes are. This distributes heat more evenly when it enters the food chamber. One must remember that air moves a lot faster through an offset smoker than in your ordinary kettle or kamado.

If unsure of which to build, start with a normal offset smoker, due to a simpler construction. That being said the reverse flow design suits smaller smokers better since the BTU (energy) in is wood high. You get slightly more even temps with the reverse flow in a small smoker.

NOTE: many first time builders I talk to have their mind set on building a reverse flow smoker since they just ‘know’ it is better. And that without even having used one, reverse flow or not. I think that is largely due to the many cheap offset smokers available on the market, which are badly designed and have large temp swings. A well constructed offset smoker has no issues with temp swings. My offset smoker ‘Rude Boy’ is a normal flow smoker, and I have a 5-8 degree temp variance in the food chamber. That is way less than most reverse flow smokers commercially available.

The Food Chamber

Start with the food chamber and calculate the rest of the smoker accordingly. Size and shape is governed mainly by two things:

- Capacity. How much food do you need to cook at once?

- Appearance. What style of smoker are you looking for?

Several grates at different levels are very common, as well as different door mechanisms. I usually measure briskets and ribs with a folding rule to be able to estimate shelf size. Make sure you measure height also to get a correct vertical distance between shelves. Regardless of size, two shelves/grates are recommended. This is to get more cooking capacity, but the temps will also be a little different (hotter on the higher grates), and this can be advantageous when smoking different cuts of meat at the same time.

The Firebox

The firebox needs good oxygen supply, and should have room for building a good fire with 5-6 logs. The purpose of the firebox is to create a fire that can warm up and hold temp in the food chamber. The size of the firebox is not related to the size of the food chamber. Why not, you may ask? Well, the heat energy in burning wood is so high that even a 4-5 log fire can sustain temps in a 1000 gallon smoker. There are various suggestions online to make the firebox a certain percentage size of the food chamber, but that simply doesn’t hold true. Take a look at really large smokers like the ones Aaron Franklin buids, and there you will see the firebox is relatively small.

Firebox Size

In general, the firebox can be smaller than you think. Pure wood has higher BTU (heat energy) than charcoal or briquettes, so even a small fire will produce enough heat. When I build a firebox I make a cardboard box as a model first. It saves a lot of time and measurements. If unsure, start with a firebox that is 50 cm wide, 50 cm tall, 60 cm deep (20″ wide, 20″ tall, 24″ deep). That size will suit most backyard size smokers. The reason for having it slightly longer is to allow for it to protrude into the firechamber, but also to be able to build your fire further in (common during winter) or closer to the door.

Is there such a thing as too small a fire box? Yes if the fire box is too small you will have issues with temp spikes in the food chamber. A certain size fire box gives you a bigger thermal mass (bigger fire box -> more metal), and also a larger buffer of hot air. Hence the general suggestion on size in the previous paragraph.

Smoke Stack Size

In order for an offset smoker to work well you need a clean burning fire. A clean burning fire requires good draught, which is accomplished with an appropriately sized smoke stack. Many commercial smokers have a smoke stack that is too thin and/or too short if you ask me. The smoke stack is the engine in your smoker. By draught I mean the amount of air being pulled through the smoker, measured in ft3/s, or m3/s if you use the metric system.

A common misconception online is that the smoke stack should be sized according to the size of the food chamber or fire box. This is wrong. Draft is primarily controlled by diameter and length of smoke stack – within reasonable limits, see below.

The size of the smoke stack is governed by how much natural draught you want. Natural draught is controlled by the temperature difference between the food chamber and the outside air. That holds true within reasonable limits.

What do I mean by that? Well, imagine a correctly dimensioned smoke stack for a 500 gallon smoker measures 10″ in diameter and is 3 meters tall. Now put that on a backyard size smoker – would that still produce the same draft? No, because the volume of the smoke stack is so much larger in relation to the food chamber. In this scenario the smoke stack needs to be scaled down proportionally.

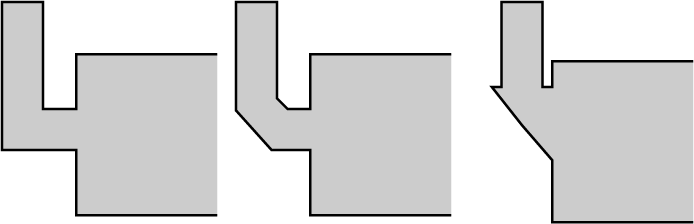

Smoke Stack Placement

Most smoke stacks are located at the very top of one end of the food chamber. Some are centered vertically.

Placement of the smoke stack is more important than you think. In an offset smoker there’s a lot of hot air moving through at a constant pace. Hot air rises, meaning it will move up to the top of the food chamber as it moves across. By placing the smoke stack lower down on the food chamber, the hot air flow will be temporarily reduced (when forced down), causing some of the hot air to transfer its heat back into the food chamber and therefore reduce the temperature differences slightly. You can place the smoke stack even lower than that if you want to, but in my experience it doesn’t help. See the image below which illustrates this back pressure.

For reverse flow smokers the smoke stack is mounted high. Due to air traveling longer in the food chamber, you want to improve draft by making it as easy as possible to get air from A to B. Also the effective height of the food chamber is reduced with the baffle in place.

Smoke stack transition (elbow)

The aerodynamically oriented may wonder if the elbow or bend should be as smooth as possible to allow the smoker to breathe fully.

You can use a 90 degree bend, or ‘soften’ it a bit in various ways. Does it really matter? A 90 degree bend will affect draught slightly, but the effect is so small it can be ignored in this type of application. An offset smoker has a lot higher air flow than a kettle grill, but at the same time it’s not a Formula 1 car either. Choose what is easy to build or that matches the look you’re after. I bought a smoothly bent (1/4 circle) pipe myself, it was the easiest way for me.

Materials – what to use

Regular steel is by far the most common material. It is generally available, and affordable. Stainless works just as well, but comes with a much higher price tag. The one material to steer clear of is galvanized steel. it contains a lot of zink (a natural part of the galvanization process), and it releases toxic gases when heated. Some may counter by saying that the temp in the food chamber is too low for the zink to evaporate, but the fire temperature in the fire box is a lot higher than that, so avoid galvanized steel at all times.

General construction ideas

The opening from the firebox into the food chamber should be as large as, or bigger than, the smoke stack size. This is to avoid throttling the air flow. So: if you ‘walk’ the path the air takes, but backwards, from the smoke stack to the firebox, each opening/aperture the air passes should be equal to, or bigger than, the previous opening/aperture.

Thanks, this is great information and is not exactly what I have been finding other places. I’m in the process of making my first offset smoker and this information will go directly into my design.

I love the info. I Am in the process of making a smoker . I appreciate the engineering info.

Thanks for these explanations. How long should the stack be? How did you calculate that? If the stack is too long, the air is cooled down and condensed. The cold air presses back into the chamber and the draft is disturbed. Or did I misunderstand something? Greetings from Germany…

That depends 🙂 If the stack is too long, the draft is too strong, meaning you get zero smoke flavor. If it is too short, the fire doesn’t burn clean enough, and you get bad smoke flavor. The trick is finding a good average. I use natural draft calculations (thermodynamics) to get close enough.

Brilliant manifesto! You’ve confirmed a few of my assumptions and have given me a lot to think about on things i didn’t consider.

The dimensions is one of my biggest worries. What I’m planning is:

– 6.35mm thick steel

– 1 meter wide, 45cm deep cook chamber

– 50cm wide, 35cm firebox

– 10cm diameter smoke stack

– smokestack will go centered on the side at grate

– the door to the firebox will have an air intake slide only at the bottom

I noticed the dimensions of the firebox you talked about is about the same as what I’m planning and you say the size for the firebox isn’t relevant to the size of the cook chamber. So does this work?

My biggest question is, how tall should i build the smoke stack? You said the size of the smoke stack friends on the amount of drought i want. So how much should I want for an ideal cook/smoke? Or should I make it bigger than need and use a damper?

Thanks again!!

Cool! The dimensions overall look good. I would make the firebox deeper, 35 cm is just barely enough to fit an ordinary log. Make it 50 cm deep instead. Make the smoke stack 80 cm tall, and you’re good.

Hi Hendrik… Could give me an advise, why there is different temperature at cooking chamber?

The temperature at end side (close to stack) is lower 20°F..

Thanks

Hi Sadie!

That’s really hard to say without seeing or knowing which smoker you have. Is it commercial or custom built? Either way, design and construction has a huge impact on how the hot air moves through the smoker. But 20° F isn’t a big deal if you ask me. All cookers have slightly different temp zones, the trick is to get to know your smoker.

I’m in the beginning phase of designing my smoker. I live north of Denver (6k ft) so I naturally have to take into account getting enough oxygen into the smoker to maintain a steady heat.

My question is if you have a design that works better/best at elevation?

Hi Nate! No, I don’t have a specific design. The ‘regular’ design works. What I do (as you may have seen) is that I run with a smoke stack with no vents. I don’t have a vent on the firebox either, I run it with the door open. That way you’re free to build the fire the way you want, and therefore also take into account high altitude.

Hi Hank, thanks for all the info! Does the wall thickness of the smoke stack matter? I am struggling to find some tubing of the right size. Right now, I am looking at a piece of tubing in these dimensions — 4″ OD x 0.065″ Wall x 3.87″ ID Stainless Round Tube 304 Welded

I am concerned this will be too thin

Hi Gino! If you can, try to find thicker material. The tube you found is so thin it will dent rather easily. But it will work, no problem, meaning it will create the draft.

Hi I’ve just built my first offset cook camber is 54”x19” old compressor tank my fire box is 18”x18”x 24” I’m currently having problems with the draft from my stack it’s currently 46” long made out off 80x80x5mm box section but am looking to modify this to some 6” pipe what length would to recommend as and average

Cheers

Hi Scott! In what way are you having problems with the draft? What does the opening from firebox to food chamber look like? Are you running with charcoal or wood? Do you have a vent in the firebox door, or is the door open? Drop me a line: henrik@hankstruebbq.com, feel free to include a few photos.

Thanks, Henrik

Hank im building a offset smoker the cooking chamber 22 by 60 im using a 24 inchby 18 firebox and a 4 inch by 34 inch pipe for a exaust vent.the cooking chamber will to firebox vent half moon with a 13.5 diameter.what do you think of these measurements and how much angle should i angle the radiant plate inside the pit

over the fire box .please tell me what you think

Hi Larry!

Those dimensions sound good. As for the radiant plate, do you have photos/drawings? Not sure what you mean. You can email me at henrik@hankstruebbq.com

Cheers

Have an offset smoker (0.25 in construction) with a cooking chamber of 20″X40″ and the smoke stack is 16″ from top of the 90º elbow, 0.25 inch tube with an inside diameter of 5.25 inches. But my cooking chamber opening to the stack is only 4.25 inches. Should I make the opening as wide as the stack diameter and increase my stack height by another 16 inches to improve the draught? The fire box is 18″X20″ with a 4.25″X8.50″ opening to the cook chamber.

Hi Jorge! I would say yes. The opening, going backwards, should be equal to the smoke stack size or larger. That way the smoke stack is the controlling factor. And your stack is a bit short, 16″, so double it.

Cheers, Henrik

Hello Henrik, I’ve recently purchased an old country brazos with these same dimensions and plan on removing the stack and adding a smoke collector with a taller 5” schedule 40 stack, my question is that I live in central Florida and having a hard time determining how tall the stack should be and wondering if the smoke collector will offset some height due to better flow? I have one shot at getting this right? Any advice would greatly be appreciated! Thanks and love the content!!! Troy

Hi Troy!

So, if I understand you correctly you want to replace the old stack with a new one that is 5″ in diameter and 40″ tall? Plus a smoke collector to fit it to the smoker. I think 40″ is a bit tall. Given that you will add a smoke collector that will be 4″ tall (guessing here, but that should be about right) I would make the stack 30″ tall, no more.

Cheers, Henrik

Thank you so much for your thoughtful advice to all us future Smoke Masters.

Hello Henrik,

Thanks a lot for all the information and recipes too, I really appreciate the knowledge I got from your website, and Videos.

I have questions regarding the design of the traditional smoker, does the size of the opening between the Firebox and the cooking chamber relate to the size of anything else? in other words how to decide the size of this opening?

I am after an even heat distribution across the smoker, so if I add a deflector (water Pan shelf similar to the one in Franklin commercial Pit) would it help achieve that?

Thanks a lot

Hi Ahmed,

and thanks! Yes, that opening should be bigger than the area of the smoke stack. You want the smoke stack to be the one factor controlling draft. And yes, adding a water pan will control air flow. Hot air rises, and the water pan blocks the upwards air flow.

Thanks a lot, Hank that is very helpful, I have a friend who is building me an offset with the following measurement

square firebox H 60 x W 76 x L 76

Cooking Chamber is 76 cm Diameter x 150 cm in length

I have 2 questions if you don’t mind, please.

my friend suggests the smoke stake to be 17.5 cm diameter x 104 cm length (from the bottom of the smoke collector to the top of the stake), is it ok? I feel it should be taller, what do you think?

Also, the stake’s length should be measured above the Cooking champer or the actual length from the collector to the top of the stake?

Thanks again

Hi,

the smoke stack should be measured from collector to the top of the stack. The collector is usually small enough (height-wise) to be ignored. The 104 cm length sounds ok to me given the large diameter.

Cheers, Henrik

Hi, how are you I love all the information on this site, I’m praying to build me offset smoker, 45″ cooling chamber and 20″ firebox , my question how big should a make the cooling chamber door.

Hi! That’s up to you, there’s no fixed rule. Make it conveniently large. If you plan on building slide out racks then account for that.

Hey there,

Making an offset smoker with a 20″ x 42″ cooking chamber, 20″ x 16″ firebox(1/3 size of cooking chamber). I have used a BBQ calculator I found online. The calculator suggests a 34″stack if I use 3″ pipe or a 20″ stack if I use a 4″ pipe, both which come to 5% of the firebox volume. Does this seem right? Also suggested were a 40 sq.in. vent in the fire box and a 40 sq.in. firebox to cooking chamber opening? Please help, first build.

Hi Zac! Thanks for writing. Unfortunately I get a lot of these requests, and I just don’t have the time to answer them all. I would advise you to check out some commercial smokers with good reviews and try to copy/mimic their dimensions. Sorry for not helping out, I hope you understand. Anyway, I hope you build that smoker and enjoy cooking on it!

Hi Hendrick I built an offset smoker and I’m having problems with the draft and dirty smoke. My fire box is 18 inch square the tank is 70 inch round and 35 inch long my fire box opening to the cook chamber is 4 inch tall by 12 inch wide. Then I have a 6.5 inch tall by 16 inch wide opening into the chimney collector with a 5 inch by 22 inch tall chimney. Is there something that I should change? Thanks Tony

Hi Tony!

I don’t see any obvious issues with those measurements. Dirty smoke is not just related to the dimensions of the smoker, that is related to how you build your fire also. Try using smaller pieces of wood (not sure what you use now). For a backyard size smoker like this you could play with both the length of the logs/splits, as well as thickness. You could extend the length of the smoke stack 4-6 inches if you want, but again I don’t think that’s needed.

I’m sorry, but this is wrong. You’ve said the stack size is not related to the cook chamber or firebox size because natural draft is governed by the temperature differential between the cook chamber and the outside air. This is generically true. However, as an engineer, surely you’re aware of the effect of placing a larger stack on a smaller cook chamber. If I were to mount the stack from my 250 gallon an my tiny backyard smoker the stack would move the same volume of air but since the cook chamber is much smaller it dramatically increases the velocity of that same volume of air. This would burn the food inside. The stack does need to be sized appropriately to the cook chamber. The same goes with the firebox, as you stated, you don’t want to throttle airflow, this means your firebox must be large enough to house a clean burning fire but also have a large enough opening so as to not restrict airflow. The firebox also needs to be sized appropriately so as to house the correct volume of air necessary to carry the heat and smoke through the cook chamber. An undersized firebox will result in airflow problems. An oversized firebox will result in a pit that has temp spikes. What you said about walking the path the air takes backwards and having each opening at least it’s large as the one preceding is true for a standard flow but not a reverse flow. The baffle plate gap does NOT need to be as large as the exhaust opening. Furthermore, on a reverse flow you want the stack mounted high, not at grate level, and the firebox mounted low. I could go on but I just feel like this misinformation could lead folks to waste their time and money building a pit that doesn’t function properly.

Hi, and thanks for taking the time to leave a comment. This is some really good and detailed feedback, I appreciate that. To paint a bigger picture I wrote this a while back because I was frustrated by the many times wildly different advice and recommendations available online, including so called calculators which was an interpolation of vastly different size smokers. But in all fairness this page and its content could do with some updates, as well as some more nuances around certain details. I have done that now, and will keep updating it in the next few days.

Thanks, Henrik

Hi there Henrik,

I’m trying to build a 40″ x 23″ reverse flow offset . Couple questions as I wasn’t quite sure on the details. What size fire box would you recommend? Also firebox/food chamber opening and baffle plate opening do they have to match ? And does stack height and opening matter? Cheers ,any help is appreciated

Hi Zak!

Sorry for a late reply. Good fun getting started with a reverse flow offset! I would recommend a firebox that measures 20-24″ deep/long, and 22″ wide. The firebox/food chamber opening (area) needs to be as big as the smoke stack, or slightly bigger. Put a 4″ smoke stack on it, 32″ tall. I would match the baffle plate opening with the firebox/food chamber opening, just to be on the safe side. I built a few reverse flow offsets, and the “hole” where the air turned around from underneath to above the baffle plate was as wide as the smoker, and 4 inches “deep”. Good luck with the project!

Hi, i am a welding and fabrication teacher for a local college here in denver and this class i decided to make a smoker (reverse offset). it will be a smaller one, i currently have a 10″x10″x3/8″ square tube 26″ long that i will be using. yesterday i made my firebox 10″x10″x3/16″ and it is 12″ long. is there such thing as too big of a firebox? with my calculations it is about half the size of the cooking chamber? my firebox to cooking chamber inlet will be the full length 10″ by 1″. thank you for your help.

Hi, sounds like a fun project! Why go with the thinner material for the firebox, and thicker material for the food chamber, instead of the other way around? The firebox size is ok, in fact if I had the choice I would make it slightly longer. 12″ is barely enough to fit one log in there. But it all depends on which fuel you plan on using.

Hi Henrik!

Thanks so much for the detailed manifesto. You really made sense of a lot of info i was looking for!

I am going to build my first smoker and would appreciate your advice on using a vertical chamber as a smoke stack, as well as the main horizontal chamber. I saw some commercial designs like that and I’m having trouble figuring out the pros and cons. I have the parts and tools, and experience with other DIY welding projects, so the real consideration for me is the impact on performance and options of use. I’d really appreciate any thoughts you have on this. Thanks!

Hi, and thanks!

I must start by asking why you want a horizontal as well as vertical? The vast majority of smokers are horizontal, and it’s a solid working style of smokers that breathes well.

This is great and the information is very helpful. What thickness of metal do you recommend for a firebox, I’m planning on lining the bottom with firebricks to help keep it from warping.

Thanks Aron!

Well, if you think the bottom is gonna warp then the metal is too thin 🙂 I would go with at least 1/4″. The firebricks are there to provide thermal mass first and foremost, and secondly to protect the metal.

Cheers, Henrik

Hi Henrik,

Contemplating building a reverse smoker, have 5mm plate

Also 2m of 100mmx3mm box

For the stack, the cooking area would be 500mm wide base x500mm high to the back,

The front would be 100mm lower length 1000mm

the fire box 400w x500L x500D mm Would a series of 5mm plates

Cut into 200mm sections placed 50mm above the firebox opening across the full width of the base whereby they could slide individually to controll air flow

I would be most grateful for your comments

Regards Don

Hi Don,

that sounds like a good plan to me. Good choice of materials and dimensions. The very first plate could probably be doubled in thickness due to it taking all the heat. As for the fire box opening: 50 mm sounds ok, but could probably be increased a little, but that depends on the actual size of the “hole” the hot air has to pass. And the direction, if that makes sense. If the hole is horizontal, i.e. hot air moves horizontally into the bottom of the food chamber, then you’re fine. If the hot air comes in vertically, then 50 mm seems just a bit too small.

Cheers, Henrik

Hi, I’m building a 1000 gallons smoker and there are so many different versions about the firebox size.

Should I go with half a 250 gallons or half a 500 gallons ??

Hi Bernard! I would go with half a 250 gallon. The firebox doesn’t need to be that big per se, but if you can make it longer rather than taller then do so.

Hi Henrik I am in the process of getting my first pit built and looking for some friendly advice. I’m having trouble deciding on the dimensions. The pipe I’m going to use is roughly 60″ long with a diameter of 20″. I’m thinking of a firebox w 20″ L 22″ H 22″ and a smoke stack of 30″. I could really use some help thank you.

Hi John! What diameter stack do you plan to use? 30″ sounds a bit short.

I have a pipe that is 4 1/2″

Thanks. In that case I would use a 50″ tall stack to get better draught.

I am building a offset smoker out of a propane tank. The cook chamber is 48” x 24” with a firebox 23” by 20” round. No vents in the firebox just the door. I am putting a 6” x 60” tall smoke stack with the collector centered on the cook chamber and bottom grate. How does this sound?

Hi Jay! Everything sounds good, but the smoke stack is way too big in my opinion. I would use a 5″ pipe that’s 32″ tall instead.

Just registering my interest

Does the shape of the smoke stack matter? Meaning if I created one form flat stock would it be as good as one from tubing?

Not sure what flat stock means, but if you’re thinking of fabricating a square tube instead of a round one, then yes you’ll be fine. The length and cross section area determines draft.

I have an old oil tank 33″ X 60″ and a smaller tank 30″ X 31″ for the fire box and they are both round. What size stack should I use? Is the fire box too big? How big should the hole be where the chamber and the fire box meet? Thank you.

Hi Danielle! The fire box could be made smaller, preferrably by building a box inside that box. That will get you an insulated fire box, and also decrease size a bit. I would use a smoke stack that is 15 cm in diameter, and 1.2 meters long. Make the hole between firebox and food chamber slightly larger than the smoke stack area (i.e. at least 10% larger than 15 cm in diameter. The whole can be rectangular, as long as the area of the rectangle is larger than the area of the smoke stack. A rectangular hole is easier to cut, and it also distributes air better in the food chamber.

Hi Henrik, nice article. This info is hard to find online, thanks for sharing.

I want to build my offset and old propane tank (1000L, that’s approx. 260gallon) with which is 2.2m long and has a dimension of 80cm

I’m planning for:

– a firebox of 80x50x60cm (WxHxL)

– a stack of 1.2cm high and 15cm diameter

I intend to put the firebox a bit higher so the heat enters the tank above the grill grate instead of under. In other words the heat would “fly over” the proteins which are located near the firebox. Might this affect the over flow in any way? Are there disadvantages to your opinion?

Are the dimension of the stack good enough? Or should I go for a higher/wider stack?

Hi Dimitri,

That sounds like a fun project! I would change the dimensions around for the fire box so it is 80 cm long (deep). You want more of a “tunnel” for the fire box so you can build the fire far in, or close to the door (depending on season). As for mounting the fire box higher: I would try and avoid that. Hot air rises anyway, and most commercial smokers that have the firebox to food chamber opening at grate height (or higher) then provide a baffle of sorts to direct air down. There’s a risk that hot air will travel across the ceiling of the smoker. If you have two shelves then there will be a large temp difference between upper and lower. The stack sounds about right, perhaps increase length to 1.5 meters.

Cheeers, Henrik

Henrik! This site is awesome! Thank you for sharing with us!

I really struggled with the idea that the firebox must be 1/3 of the cooking chamber. It just didn’t make sense once large enough for fireplace sized logs if you would ultimately build a similar sized fire in each.

I am building an offset on a trailer with a 30.5” diameter cooking chamber 70” long (~220 gallons). For firebox I am hoping to make a 24” diameter pipe 24” long work and then fully insulate with ceramic wool and an outside shell of 30.5”. Both the inside pipe and outside shell of the firebox are 1/4” thick mild steel. For smoke stack I have a 5 foot long piece of 6” ID mild steel pipe with a 1/4” wall. Does that sound about right? I have been worried the firebox would be too small… at least until I found your site.

Thanks!

Hi Matt!

Yes, that 1/3 rule is really strange. It works if the food chamber is one specific size, but not as a general rule 🙂

For that size food chamber your suggested firebox size will work just fine. And the insulation will help also. As for the smoke stack: I would not make it bigger, because it will create a very good draught. Also a 1/4″ wall sounds very thick, it’s gonna weigh a lot. If you can, try and use a 5″ pipe instead.

Hi Henrik!

I built an offset with 24,41″x52,56″ cc and 23,62″x27,48″ fb. I m putting a 5,90” x 46,85” tall smoke stack with the collector centered on the cook chamber at grate level. What do you think? Is this stack the right size? How does this sound? Stack collector is 5.90″ tall.

Hi! The overall dimensions sound good, but with that smoke stack I think you will get too good draught. My smokers are of similar size and I use a 5″ stack that’s 30″ tall. I think those dimensions would be a better fit.

Cheers, Henrik

Thanks Henrik!

What do you think? if I shorten the chimney to 30″, but keep the diameter it will be better?

Yes, that sounds better. I would even shorten it to 28”, given the diameter. You will have good draught with those dimensions.

Thanks Henrik!

I will try it!

Merry Christmas!

Merry Christmas to you too!

Hank, I am building a smoker out of 390 gallon tank. Dimensions are 30”x120”. Firebox will be 20”x36” pipe. What dimensions should my smokestack be and is there an advantage to using a smoke collector over just putting a 90 right out of the cook chamber?

Hi Steven, sounds good.

I think a smoke collector is good. Instead of going from a large dimension directly to a small dimension, the collector acts as an “adapter” to make the transition smoother. A good size smoke stack would be 6″ diameter, 60″ tall.

Cheers, Henrik

Thank you for the help, Henrik.

Hey Henrik,

Love the info and glad it goes against the mainstream on something’s. I acquired a 500 gal tank and building a new personal comp smoker. I want to get really different with it for a trailer build on it, plus the tank is more short and stubby.

The tank is 1/2 inch thick material. I want to turn it sideways and put the firebox behind it and come in from the back into the center on the bottom of the cook chamber. I’m looking to do a 24”x36” (3/8” thick) firebox and insulate it (1/4” plate). Was thinking of then doing 2, 10” pipes leaving the FB into the base of the CC and insulate them as well. Then have two smoke stacks on the top at both ends of the tank. Heat come in from the bottom and naturally rise up. Was thinking 10inch ID and both being 6ft tall? Does this seem like something that would work? Firebox to small? Stacks? Adjustable baffle plate on the inlet? Possibly with holes?

Thanks!

Austin

Hi Austin! Sounds like a cool project. And the material thickness means it’s gonna last 3 lifetimes 🙂

Just some quick feedback: not sure if I follow, but if the hot air is entering the bottom of the food chamber (and dead center), make sure you place a baffle or similar so air gets distributed left and right also. Otherwise hot air will go straight up, then follow the ‘ceiling’ of the food chamber before exiting on both sides. It all depends on the diameter of the food chamber of course, but you may get a cool zone the entire bottom half of the food chamber, which could be desirable or not. The smoke stacks seem oversized. I would go down to 6″ in dia, and cut the length in half.

Cheers, Henrik

hello. I am designing a offset smoker with a welder. The welder makes smokers of his own design in bulk but I wanted to change his design slightly. I want 120 gallon pot belly offset smoker. he states that he doesn’t usually make the smoke stacks where the 6-in internal diameter but uses 4 inch ID. what length smoke stack would you recommend? I am going to have a smoke collector. not sure of the overall dimensions yet. if you can make any recommendations for that that would help also. firebox I’m guessing 24″x24 x 18.

Hi Bobby! For a 120 gallon smoker a 4″ stack sounds perfect. The collector isn’t sensitive to size, it’s size is naturally given since it must act as a bridge between the smoke stack and the food chamber. What do you mean by a “pot belly” offset smoker? Not sure I know what that is.

I’m about to start building an offset smoker out of a 250 gallon propane tank. I am looking for any expertise on firebox size, and smokestack size and length

Hi Ashley, what are the dimensions of your tank roughly? As for firebox size, do you plan on making it round or square?

Cheers, Henrik

Approximately 92” long and 30” in diameter. I would like to stay round with the firebox also

Cool. Do you have access to the same diameter pipe for the firebox? I mean the same diameter?

If so, I would recommend a firebox which is 24-30″ long/deep. Longer is better in the winter, completely depending on where you live.

As for smoke stack, use a 5″ pipe that’s 3 ft long.

Thank you very much. I really appreciate it

I’ve be trying to research some info on my smoker project and your knowledge on this I feel is explained more in layman’s terms than other sites I’ve been to and I thank you for that. I have a couple of questions that I could use your advice on. I bought a well built grill that is all 1/4” steel construction and I’m wanting to add a firebox. So the grill is 16” in diameter and 32” wide which is going to be perfect for me and my family. The stack is 3” pipe and 24” tall in the typical upper placement protruding out of the cooking chamber. What I have to work with would be a firebox that would be 20”x24” overkill probably but that’s what I have to work with. My questions are what size for the throat opening in that situation and is my stack going to be sufficient for a cooking chamber that’s 16×32 and a firebox that’s 20×24? It’s been tough finding 1/4 steel pipe or sheets that aren’t outrageously priced but my buddy found 20”x28.5” 1/4” pipe and 1/4” sheet at auction for $100 in perfect condition. Thanks for any help on this.

Hi Eric!

Sounds like a fun project, and doable without too much effort. If that’s the firebox you have to work with, then it will be fine. You could insulate it by putting inner walls with a 1″ spacing, or just leave it as-is. One thing that is advantageous though is to add a 2nd bottom. If you google Chud’s BBQ and look at his designs he has put a V-shaped bottom plate inside his, that’s an easy mod that helps. The opening from firebox to food chamber should be bigger than the smoke stack, in this case just double it. The smoke stack size is fine.

Cheers, Henrik

Thank you Henrik. It’s awesome that that you’re so willing to share your knowledge to folks in need! Greatly appreciated sir.

Man I appreciate all of the time you put into helping us make our own smokers. Without this website i would be trying to come up with a 383 gallon firebox! (1150 gal. / 3) What size should the opening be between my firebox and cook chamber? I have an 1150 gal. tank with an insulated firebox diameter of 27″, 35″ deep. The exhaust is a 10.75″ x .188″ pipe, currently 8 feet long but I might trim it down a bit. What do you think? Thanks a ton!

Hi Graham! Thanks, good to hear you appreciate the site. So, as you’ve discovered, those calculations are a a bit off 🙂

The general rule is that the firebox to food chamber opening should be bigger than the smoke stack area, so the only “limiting” factor is the smoke stack area, meaning it is the one thing that controls the speed of air moving through the smoker. With a 10.75″ smoke stack I calculate the area to approx. 95 sq.in. So, I would make the firebox to food chamber opening 100-110 sq.in (or bigger, depending on what makes sense from a construction point of view). A rectangular opening that is 25″ by 4″ would work just fine, and if you want to make it 30″ by 4″ that works just as well.

The smoke stack is a bit too long I think, but try it out with that length and see how it behaves. It is always easier to shorten a stack than lengthen it 🙂

If the smoke is too clean (too high draft) then chop it off by 2 feet. You want to stay below 2 meters/second, I measure draft with an anemometer.

Cheers, Henrik

Hi Hank,

I love this web site. I appreciate all of your knowledge and advice. I have an Oklahoma Joe Highland offset. The thing drives me crazy. It seems like I dont get enough draft and Im constantly playing with he fire. Ive sealed the lid and I leave the door open to smoke. I still get blowback from the door and wild swings in temp. I cant build a smoker yet for I have no welder. ANy advice?

Thanks!

Hi Angelo, and thanks!

Yes, unfortunately that sounds too familiar, too many commercial smokers behave like that. There are a few things you could try though.

1. Extend the length of the smoke stack. Go to a hardware store and see if you can find a metal tube/pipe that you can simply thread on to the existing stack to make it longer. Metal vent pipes are usually easy to find, and cheap. But I would also extend it on the inside. Get some flexible vent pipe and form a soft 90 degree bend so the air intake is at grate level. This second “hack” will even out the temp in the food chamber a little.

2. Looking at pictures of your smoker, I would remove the metal grate that is located smack in the middle of the firebox and build the fire on the bottom instead. Get some fire proof bricks (4-6 should do it) and place on the bottom to increase thermal mass and protect the bottom from rusting through. The big benefit is that you will be able to build a thicker bed of glowing embers. It should allow you to do less playing with fire.

Cheers, Henrik

Thanks brother.

I tried extending the smoke stack around 24 inches with a piece of cast iron pipe I had at work. It fits perfectly over the end after removing the vent. It still didnt draw well. I will try the fire bricks too. If these options do not work, aside from building one, can you recommend a smoker that works really well?

Thanks again,

Angelo

Hi Angelo! There are many brands of offset smokers, but few that are built correctly. Not sure if you live in the US or anywhere else in the world, but here are a few brands

worth checking out:

As you can see price varies, some are expensive. As I don’t live in the US I don’t know of any local manufacturers, but you should be able to find some metal shop that can knock one out for you at a decent price. At least I wanted to throw that in there as an option.

Cheers, and good luck.

Thanks Hank. I do live in the USA, Chicago area. Ill check these out.

i have a 20” diameter pipe x48” long 1/4 thick what size fire box do i need it’s round will a 20” x 24”diameter work

Hi Mario! Yes, a 20″ by 24″ firebox will be great.

Cheers, Henrik

Hi Hank.

My name is Paul from Zimbabwe in Africa.

I am in the process of building an offset smoker with a insulated square fire box, following are all sizes.

So i am wondering if you can guide me and confirm i am on the right path, as well as info on the length and diameter of the smokestack that i need.

We work in Millimeters on this side of the pond, so my apologies for the Measurment’s being in MM.

Cook chamber is 1920mm x OD 800mm. ( measurements are taken from side to side NOT the whole circumference )

Fire Box width 670mm x depth 720mm x height 550mm.

Smokestack 200mm OD x 1800mm length. ????????

Hi Paul,

sounds like a fun project! I am living in Sweden, so millimeters is all I know 🙂

So, cook chamber is almost 2 meters long, and 80 cm i diamater?

The firebox sounds just fine, I think insulating it is a good move. It really helps. The only question I have is regarding the smoke stack. 200 mm outer diameter sounds just a bit big, with that length. It will pull quite a lot of air. Can you go down to 150 mm diameter instead, with the same length (1800mm)?

Cheers, Henrik

Hi Henrik

Thanks for the reply. I have enjoyed this platform and have learnt a lot from it. My apologies, I gave you my old email address. I have added my new one below.

Yes, I can make the stack 150mm diameter what thickness of material should I use.

On the fire box opening into the cook chamber, how far should the bottom of the fire box hole be from the bottom of the cook chamber, and if my smokestack is 150mm diameter, how big should the fire box hole be.

And what shape hole would you think works best, round, rectangular, square etc.

regards

Paul

Cool. Usually it isn’t that easy to find metal tubes/pipes with a 6″ diameter where the material is still thin. My only option (in Sweden) was to use stainless steel. But 2-3 mm will suffice, see what you can find where you live. This was actually the more tricky part of my big smoker build.

As for fire box hole size: you want the surface area of that hole to be bigger than the area of the smoke stack. For the size smoker you build a rectangular hole that measures 80-100 mm wide (in the length direction of the smoker) and 300 mm wide (across the smoker) will suffice. The shape is less relevant, i.e. it doesn’t need to be round. I use rectangular in my smokers to get as wide distribution of hot air into the food chamber as possible.

As for the hole location, and specifically how (direction wise) the hot air enters into the food chamber, that is a longer discussion. Feel free to drop me an email (henrik@capsor.se) and I’ll elaborate.

Cheers, Henrik

Hello Henrik, i’m planning to build a backyard smoker. Is it possible to make it from corten steel? Does it have disadvantages or somthing with food safe?

Hi Robert! Yes it is, i have built 8-10 of them in Corten steel. It works just fine, the only drawback is that it’s a tougher material so you will use more cutting discs for your grinder et.c. But except for that I really like it because of the look they will get after a year or so of use.

Cheers, Henrik

Hello. I’m building an offset smoker from an old water tank 540x670mm, the firebox is 400x400x400mm. How big should the hole between the tanks be? What about the size of the chimney? Is 168mm diameter too big?

I can send a picture of the tanks

Hi Jari! Yes, a photo would help. The food chamber seems a bit small (short). It will work, but you will have varying temp in the chamber, there will only be one small “sweet spot”, just so you’re aware. And the risk is that you will get too much direct heat radiation with a short tank. Just letting you know. The hole between the tanks should be bigger than the chimney area. In your case with a smaller smoker 168 mm is too big for a smoke stack. Try 100 mm instead.

Cheers, Henrik

Hi. I sent an email with pictures about the smoker and ideas

Hi. That’s how it turned out.

https://photos.fife.usercontent.google.com/pw/AP1GczP_I3ae4n5WwiWGMYAxkwV_ND_g2fyUmqVunfdJaE2_PkbrgyiVw8mvlg=w338-h600-s-no-gm?authuser=0

https://photos.fife.usercontent.google.com/pw/AP1GczNeLiIhGTE26z2Ce22XW8QNUrX6iIySIftX5s5DMkB2EBwW2ru-vHoGaA=w97-h173-no?authuser=0

Thanks Jari! Unfortunately the images don’t seem to load.

Hej Henrik!

Det är fantastiskt hur du hjälper människor:)

Jag skriver från Ungern, jag har en 64 cm lång och 42 cm bred cirkulär tank och jag vill göra en Offset-rökare. Jag designade eldstaden 35x35x35 cm, skorstenen 8cm x 60cm. Eldstaden skulle vara på 1/3 av kokkammarens höjd?

Snälla hjälp, är planen bra?

Tack så mycket: Tom

………………….

Hej Borsos!

Tack, här kommer lite feedback på din smoker. Om du tänker elda med ved är den i minsta laget, både skorsten och eldstad. Eldstaden bör vara 50 x 50 x 50 cm, men gärna längre/djupare. Dvs 50 x 50 x 70 cm. Skorstenen är för kort och för smal, du får inte tillräckligt bra drag med den dimensionen. Prova att gå upp till 10 cm diameter och 1 meter lång.

Hello,

I am building an offset smoker from a 120 gallon tank. 69” long and 24” Diameter. I am thinking a 24” diameter firebox, 26” long. 5” smoke stack 35” tall from collector, which will be placed at center line of smoker. Do these dimensions sound correct?

Hi Matthew!

Sounds like you have a fun project going! Yes, I think the overall dimensions sound good. The one thing I would adjust is the length of the firebox. 24″ in diameter is fine, but if you have the possibility to do 28-30″ length instead I think it’s better. Main reasons (I live in Sweden, i.e. up north):

Long story short: I find it useful to have the option of moving the fire further in or closer to the door depending on the weather.

Good luck!

Thanks for the reply on my 120 gallon offset. I ended up going with 24” diameter and 27” long. Living int he southern US I don’t really have to fight the weather. What cubic inch would your recommend the firebox to cook chamber opening? I’m thinking 100 sqin.

I assume you mean square inches? 100 sq in sounds very large, that would be 20” by 5”. It needs to be bigger than the smoke stack area, but not huge. Given a 24” diameter of the food chamber I would make a rectangular hole 14” by 3”. That’s plenty for proper air flow.